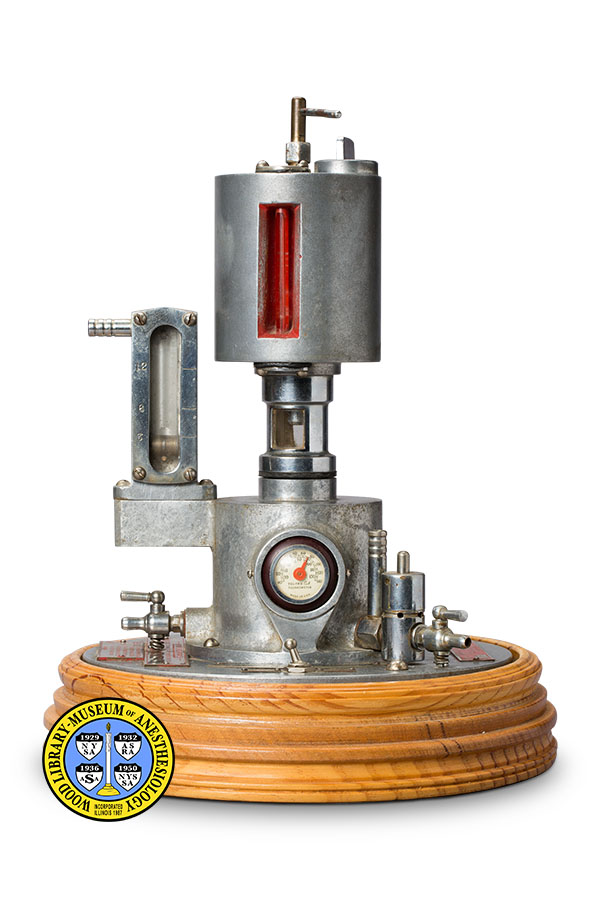

Clements Vaporizer

Australian inventor and engineer Hubert Ingham Clements (1886-1969) founded his manufacturing company in 1908. One of the first medical devices they made was an endotracheal insufflation anesthesia apparatus. This technique, popular through the first half of the 20th century, delivered anesthetic vapor through a tube inserted in the patient's trachea (windpipe.) The example shown here was probably made between 1930 and 1950.

The cylinder at the top is an ether reservoir, with a drip feed tube that leads to a vaporizing chamber below. The lower cylinder surrounds the vaporizing chamber with a water bath that was heated by electricity. A motor (not present in this example) drew air into the chamber, where it became charged with the ether vapor, and then out again toward the patient. It was noted that this design required the water to be so hot that it could potentially cause an unsafe concentration of the vapor. But Clements' products were well respected, and over 900 of its insufflation anesthesia apparatus were sold before the company changed hands in 1967.

Catalog Record: Clements Vaporizer Clements Vaporizer

Access Key: amxu

Accession No.: 2007-08-12-1

Title: [Clements Endotracheal Anesthesia Apparatus].

Author: Clements, Hubert I. (Ingham), 1886-1969.

Corporate Author: H. I. Clements.

Title variation: Alt Title

Title: Clements Anaesthetic Apparatus.

Title variation: Alt Title

Title: Clements Ether Vaporizer.

Publisher: Sydney, Australia : H. I. Clements, [between 1917 and 1962].

Physical Description: 1 endotracheal insufflation anesthesia apparatus : metals, glass, rubber, paint ; 30.5 x 22 dia. cm.

Subject: Anesthesia, Inhalation – instrumentation.

Subject: Anesthesia Machines.

Subject: Ether, Ethyl.

Web Link: https://www.woodlibrarymuseum.org/museum/item/1010/clements-vaporizer

Note Type: General

Notes: The title is based on the common elements in the names of various models of the apparatus. The cataloged object is not an exact match to any known description. The first year in the date range is based on the date of the company’s entry into the field of anesthesia equipment manufacture. The second year in the date range is based on the date when the company ceased production of ether apparatus; this example’s low serial number (315 out of a total of 933) makes it likely that it was produced somewhat earlier. In this description the front of the apparatus is considered that side on which the flowmeter and the thermometer can be read.

Note Type: With

Notes: 1 wooden stand : 5.5 x 26.5 dia. cm.

Note Type: Citation

Notes: Ball C. The Lidwell machine. Anaesthesia and Intensive Care. February, 1990;18(1):4.

Note Type: Citation

Notes: Clements Company File. Archives. Located at: Wood Library-Museum of Anesthesiology, Schaumburg, Illinois.

Note Type: Citation

Notes: Elliott Brothers Limited. Illustrated Catalogue, Surgical Instruments and Appliances, Aseptic Hospital Furniture, Electric Appliances, Diathermy Apparatus, etc., and Hospital Supplies, 5th ed. Sydney: Elliott Brothers Limited, 1929.

Note Type: Citation

Notes: Holland R. Hubert Ingham Clements: a pioneer of Australian anesthesia. Anaesth Intensive Care. June, 2005;33(Supplement 1):4-6.

Note Type: Citation

Notes: Holland R. Decline and fall–a tragedy in three acts. Anaesth Intensive Care. June, 2007;35(Supplement1): 11-16.

Note Type: Citation

Notes: Kaye G, Orton RH, Renton DG. Anaesthetic Methods. Melbourne: Ramsay (Surgical) Pty. Ltd., 1946:158-159.

Note Type: Physical Description

Notes: One endotracheal insufflation anesthesia apparatus; The height of the apparatus alone is approximately 32 centimeters; When seated in the wooden stand, the total height is approximately 35.5 centimeters; The apparatus could not be used while seated in the stand; The upper component of the apparatus is a cylindrical ether reservoir; At the bottom of this cylinder is a drip feed tube that connects to a second cylinder below; This lower cylinder is attached to a circular metal base plate;

On top of the ether reservoir there is a vertical post with a horizontal arm; Mounted in a hex nut, this post can turn 360 degrees both to the left and the right; Also on top of the reservoir, to the left of the post, is an ether fill port which is fitted with a screw cap; The back of the reservoir has an inset area that holds a glass tube for viewing the level of the ether; Behind this tube, the inset portion of the wall of the reservoir is painted red; At the bottom of the reservoir is a drip feed that has a glass window on the front and another on the back; The reservoir and drip feed form one solid column, which is screwed into the cylinder below; This column can be easily removed and replaced;

The lower cylinder contains a vaporizing chamber which is surrounded by a space that can be filled with water (a water bath); The bottom of the drip feed connects to the vaporizing chamber; This cylinder holds four components: 1) a round thermometer mounted on the front, 2) a flowmeter mounted on the left, 3) an ether drain stopcock mounted directly below the flowmeter, and 4) a vertical metal tube, connected to a stopcock, mounted on the right (the fill port and drain cock of the water bath);

The flowmeter is marked, from top to bottom, “12, 6, 3”; Near the top of the flowmeter, and extending to the left, is a short metal tube that would connect to a breathing tube;

The thermometer dial has a red needle indicator, and is marked with two numbered rings; The outer ring reads, from left to right: “-40, -20, 0, 20, 40, 60, 80, 100, 120, 140”; The inner ring reads, from left to right: “-30, -10, 10, FRZ, 50, 70, 90, 110, 130”; The center of the dial is marked “Tele-Tru Cub [new line] Thermometer [new line] Made in U. S. A.”;

The lower cylinder is connected to a round base plate by three screws; The base plate holds a toggle switch, mounted directly in front of the thermometer; The switch is marked, from left to right; “HEAT OFF”; A metal label is screwed to the plate directly in front of the thermometer, between the cylinder and the toggle switch: This label reads: “IMPORTANT, HEAT IS NECESSARY [new line] KEEP HOT”;

Two more metal labels, each screwed to the plate, are located directly below the stopcock on the left; That label closest to the cylinder reads: “BEFORE USING APPARATUS [new line] BE SURE [new line] TO DRAIN OFF ANY ETHER, THAT MAY BE IN [new line] VAPORIZER CHAMBER, BY MEANS OF [new line] COCK “A” ABOVE”; The outer of these two labels reads: “BE SURE [new line] TO HAVE AIR PASSING THRU [new line] FLOWMETER BEFORE ETHER [new line] DRIP IS TURNED ON, OTHER [new line] WISE ETHER WOULD ACCU- [new line] MULATE IN VAPOR CHAMBER”;

To the right of the right-hand stopcock, a fourth metal label reads: “SCIENTIFIC APPARATUS [new line] MADE BY [new line] H. I. CLEMENTS [new line] Engineers Sydney”; [new line] No. 315″;

The base plate has three screws that do not attach to anything; These screws extend approximately 2 centimeters below the plate, and act as supporting “feet” for the unit; An enclosed electrical component is attached to the underside of the plate; The electrical component is controlled by the toggle switch mounted on the surface of the plate; A length of rubber-encased electrical cable exits this component; This cable has been cut short.

Note Type: Reproduction

Notes: Photographed by Mr. Steve Donich, January 12, 2016.

Note Type: Acquisition

Note Type: Historical

Notes: In use throughout the first half of the 20th century, endotracheal insufflation anesthesia delivered anesthetic vapor through a tube inserted in the patient’s trachea (windpipe.) Some insufflation apparatus was coupled with a component for warming the anesthetic, and some with a motor to supply forced air and/or suction. The Clements apparatus was accompanied by a motor, and could be purchased with an optional suction component.

Australian inventor and engineer Hubert Ingham Clements (1886-1969) founded an automotive repair business, H. I. Clements, in 1908. He became a respected leader in the automotive industry. After WWII, the company changed its name to H. I. Clements & Son. The company was sold in 1967, and continued making medical equipment under the name H. I. Clements Pty. Ltd. (i.e. Propriety Limited) until 1987, when the name was changed to Phoenix. Phoenix was dissolved in 1994 (Holland, 2007, p. 14.)

According to an unsigned and undated history of the company, Mr. Clements made his first medical device, a suction pump, in 1912. Holland states that the company “forsook the motor industry altogether and concentrated on medical and scientific apparatus”, selling its anesthesia and suction equipment to “almost every hospital in Australia” (2005, pp. 5-6.)

An advertisement dated 1938 states that the company then had “21 years of experience in the manufacture of anaesthesia apparatus.” Holland states that Clements’ first anesthesia apparatus was produced at a commensurate date, 1917, when, “in collaboration with Dr. Mark Lidwill, he designed and manufactured a mechanical vaporizer, a machine which remained in use for many years under Lidwill’s name” (2005, p. 4.) Set against this account, Ball gives Lidwill sole credit for designing an insufflation anesthesia apparatus in 1913, which was “manufactured by” Elliott Brothers, of Sydney. Elliot’s 1929 catalog, in the WLM collection, features a Lidwill apparatus. The cataloger was unable to determine whether both of these authors refer to the same machine.

According to a brief company history by Michael G. Cooper, M.D., dated June, 1994, Clements began manufacturing insufflation anesthesia apparatus in the 1930s. Holland states that Clements’ various models “included warmed-water versions, but from the 1950s electric heating gradually became more popular.” (2007, p. 13.)

Cooper states that the company’s production of ether/air apparatus ended in 1962. Holland states that the production run was under 1000, the last one being sold in 1967 (2007, p. 13.)

In 1946, Kaye described, but did not identify, an apparatus which is very similar to that made by Clements. In that description, an ether reservoir is set above a vaporizing chamber, with a glass window in the drip feed that stands between the two. The vaporizing chamber is surrounded by a water bath. Air is taken in through an inlet, passes through the chamber and out again toward the patient. Kaye noted that the disadvantages of this design were that “the water must be really hot”, and that “if the supply of air be turned off without closing the screw valve”, the patient would receive vapor “of boiling ether”, which “may well lead to a calamity” (p. 158.)

Note Type: Exhibition

Notes: Selected for the WLM website.