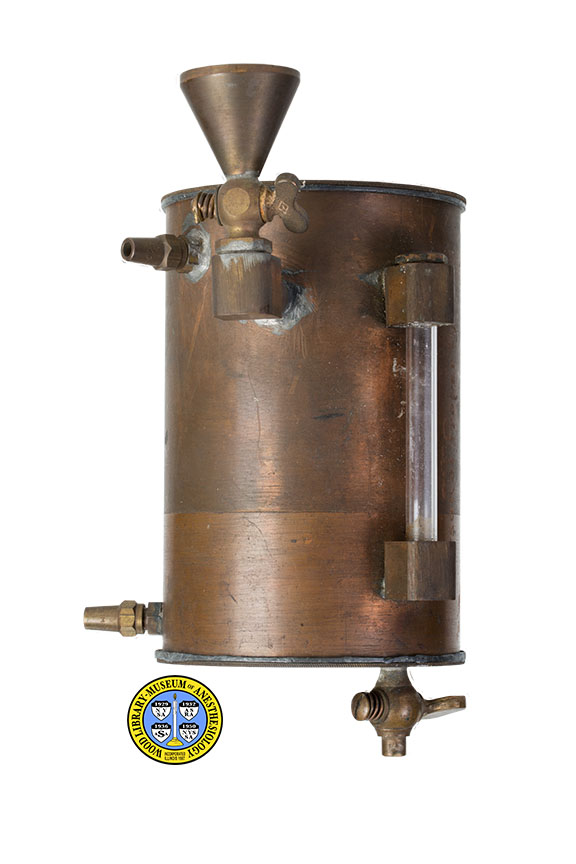

Copper Kettle Prototype

Copper Kettle “Wisconsin Prototype”

As anesthetic liquids are vaporized, their temperature drops. Variations in temperature, in turn, can impact the performance of the vaporizer. Lucien E. Morris, M.D. (1914-2011) designed the Copper Kettle Vaporizer to perform with great accuracy, in part by maintaining a constant temperature. He began work on it in 1948, while a resident under Dr. Ralph Waters at the University of Wisconsin, Madison. The commercial model was manufactured by the Foregger Company, of New York from 1952 through the 1970s.

The design was a departure from that of its predecessors in three important ways. First, most vaporizers added an unknown concentration of vaporized liquid to a measured amount of gas; the Copper Kettle allowed the vapor to be added in known quantities that could be precisely measured and controlled through a separate circuit built into the anesthesia machine. Second, heat is required to convert volatile anesthetics from the liquid to gas form. Most vaporizers were made of glass which conducts heat poorly and so the temperature of the liquid in the vaporizer dropped rapidly in use; the Copper Kettle is made from materials that conduct heat well, keeping the liquid warm. Third, by dispersing the carrier gas through the liquid in a large number of very small bubbles, it further increased the speed and efficiency of vaporization.

The Copper Kettle could be calibrated to vaporize any volatile liquid anesthetic, such as chloroform, ether, halothane (Fluothane), or enflurane (Ethrane). Dr. Morris intended the vaporizer to be carefully adjusted by the anesthesiologist in response to the changing needs of the patient throughout the course of an anesthetic.

Catalog Record: Copper Kettle Prototype

Access Key: amed

Accession No.: 2010-09-23-7 J

Title: [Copper kettle Wisconsin prototype] / [designed by Lucien E. Morris.]

Author: Morris, Lucien E. (Ellis), 1914-2011.

Title variation: Alt Title

Title: [Prototype side-fill copper kettle vaporizer]

Publisher: [Madison, Wisconsin?] : [Name of manufacturer not identified], [Not earlier

than 1948 and not later than 1972].

Physical Descript: 1 vaporizer : copper, glass, metals ; 22 x 14 x 16 cm.

Subject: Anesthesia, Inhalation – instrumentation.

Subject: Vaporizers.

Subject: Chloroform – administration & dosage.

Subject: Morris, Lucien E. (Ellis), 1914-2011.

Note Type: General

Notes: Cataloger constructed descriptive title based on Foregger catalog no. 12,

1955, pp. 14-23, two articles coauthored by Feldman and Morris published in

1958, and the donor’s inventory. Date range based on published and

unpublished accounts by the inventor, and other publications (see historical

note).

Note Type: General

Notes: The Lucien Morris Collection consists of both personal papers and equipment.

The inventory provided by the donors in 2010 includes one vaporizer,

described as “Copper vaporizer made in shop @ Wisc., original effort for

sintered bronze”. The object cataloged in this record is the only vaporizer

received from the donors in 2010.

Note Type: Citation

Notes: Dorsch JA, Dorsch SE. Understanding Anesthesia Equipment: Construction, Ccare

and Complications. Baltimore, MD: Williams & Wilkins; 1975.

Note Type: Citation

Notes: Feldman SA, Morris LE. Vaporization of halothane and ether in the copper

kettle. Anesthesiology. September-October,1958;19(3):650-655.

Note Type: Citation

Notes: Foregger R. Death of a Company. 2nd ed. Milwaukee, WI: Richard Foregger; 2000

Note Type: Citation

Notes: The Foregger Company. Catalog No. 10. New York, NY: The Foregger Company;

1952.

Note Type: Citation

Notes: The Foregger Company. Catalog No. 12. New York, NY: The Foregger Company;

1955.

Note Type: Citation

Notes: The Foregger Company. Catalog No. 16. New York, NY: The Foregger Company;

1960.

Note Type: Citation

Notes: The Foregger Company. Anesthesia Apparatus, Catalog 17. New York, NY: The

Foregger Company; 1962.

Note Type: Citation

Notes: The Foregger Company. Copper kettle. Roslyn Heights, NY; The Foregger

Company; 1966.

Note Type: Citation

Notes: Inventory from the donor, Lucien E. Morris, M.D. Accession file 2010-09-23-7.

Located at: Wood Lilbrary-Museum of Anesthesiology, Schaumburg, Illinois.

Note Type: Citation

Notes: Morris LE. CHCl3 Analysis [a notebook in the Lucien E. Morris, M.D.

Manuscript Collection]. 1947-1948. Located at: Wood Library-Museum of

Anesthesiology, Schaumburg, Illinois.

Note Type: Citation

Notes: Morris LE. Copper kettle revisited. Anesthesiology. April,

2006;104(4):881-884. https://anesthesiology.pubs.asahq.org/article.

aspx?articleid=1923446&resultClick=3. Accessed July 31, 2015.

Note Type: Citation

Notes: Morris LE. A new vaporizer for liquid anesthetic agents. Anesthesiology.

November, 1952;13(6):587-593. https://anesthesiology.pubs.asahq.org/article.

aspx?articleid=1971308&resultClick=3. Accessed July 31, 2015.

Note Type: Citation

Notes: Morris LE, Bamforth B. Interview with Lucien Morris by Betty Bamforth [DVD].

Park Ridge, Illinois: Wood Library-Museum of Anesthesiology; 1981. John W.

Pender Collection of the Living History of Anesthesiology.

Note Type: Citation

Notes: Morris LE, Feldman SA. Considerations in the design and function of

anesthetic vaporizers. Anesthesiology. September-October,1958;19(3):642-649.

Note Type: Citation

Notes: Morris LE, Feldman SA. Evaluation of a new anaesthetic vaporizer. Anaesthesia

January, 1962;17(1):21-28.

Note Type: Citation

Notes: Morris LE, Morris DC. The development of the copper kettle with comments on

vaporizers that preceded and followed. In: Eger EI, Saidman LJ, Westhrope RN,

eds. The Wondrous Story of Anesthesia. New York, NY: Springer, 2014:715-721.

Note Type: Citation

Notes: Morris LE, Schroeder ME, Warner ME. Ralph Milton Waters, M.D.: mentor to a

profession: proceedings of the Ralph M. Waters symposiuim on professionalism

in anesthesiology, Madison, Wisconsin 2002. Park Ridge, IL: Wood

Library-Museum of Anesthesiology; 2004.

Note Type: Citation

Notes: Sands RP, Bacon DR. The copper kettle: a historical perspective. J Clin

Anesth. September, 1996;8:538-532.

Note Type: Citation

Notes: Schreiber P. Anaesthesia Equipment: Performance, Classification and Safety.

New York, NY: Springer-Verlag; 1972.

Note Type: Physical Description

Notes: One prototype of a vaporizer, made almost entirely of copper; It is

cylindrical in shape, with protruding parts;

The top of the cylinder is a flat, threaded plate, 10.5 cm in diameter, that

screws into the body of the cylinder; The upper surface of this plate has two

shallow holes, .5 cm in diameter, that do not penetrate the full thickness of

the plate; This plate can be unscrewed to open the barrel; A rubber gasket

ring is set between this plate and the barrel;

Immediately below the top plate, a port or nipple, 3 cm in length, extends

outward from the wall of the cylinder; The port penetrates the wall of the

cylinder, connecting to a metal tube about 4 cm in length that extends into

the cylinder; This tube connects to a metal disc that has an opening in its

center on the side facing the bottom of the cylinder;

Approximately 3 cm to right of this port, an elbow connection extends 4.5 cm

outward from the wall of the cylinder; The elbow joins a funnel, called “a

side arm funnel for filling the container” (Morris 2006); The funnel rises 5

cm above the elbow; The opening of the funnel is 3.5 cm in diameter at its

widest point, which stands 3 cm higher than the top plate; A stopcock is

mounted in the base of the funnel; The funnel functions to admit liquid to

the container; The cataloger did not test the functionality of the stopcock,

which is stiff and difficult to turn;

Approximately 4 cm to the right of the funnel, a clear glass tube is mounted

in two copper blocks (one at each end of the tube); These mounting blocks are

secured inside the wall of the cylinder, each with a circular opening that

accesses the tube; When the container is filled with liquid, a portion of the

liquid enters the tube through these openings, so that the tube functions as

a gauge to the level of the liquid in the barrel;

The bottom of the barrel consists of a permeable Porex disc (made of sintered

bronze); This disc is mounted 1.5 cm above the bottom of the cylinder;

The bottom of the cylinder is another flat, threaded plate, 10.5 cm in

diameter, that screws into the body of the cylinder; The upper surface of

this plate, also, has two shallow holes that do not penetrate the full

thickness of the plate, and a rubber gasket ring;

Between the Porex disc and the bottom of the cylinder there is a shallow

space with an inlet port in the wall of the cylinder for the admission of the

carrier gas under pressure; The inlet port is mounted 1 cm from the bottom

of the cylinder, and extends 3 cm outward from the body of the cylinder;

A stopcock, 3 cm in length, is mounted on the bottom plate; This stopcock is

placed 1.5 cm to the right of the lower mounting block of the glass tube; The

stopcock does not function, as it does not penetrate the bottom plate;

Removal of this plate reveals a shallow space below the Porex disc;

Parallel to the mounting blocks of the glass tube, the wall of the cylinder

is etched: “Personal Property of [new line] L. E. Morris, M.D.”

Note Type: Reproduction

Notes: Photographed by Mr. Steven Donisch, January 12, 2015

Note Type: Historical

Notes: As anesthetic liquids are vaporized, their temperature drops. Variations in temperature, in turn, can impact the performance of the vaporizer. Lucien E. Morris, M.D. (1914-2011) designed the Copper Kettle Vaporizer to perform with great accuracy, in part by maintaining a constant room temperature. He began work on it in 1948, while a resident under Dr. Ralph Waters at the University of Wisconsin, Madison. The commercial model was manufactured by the Foregger Company, of New York from 1952 through the 1970s.

The design was a departure from that of its predecessors in three important ways. First, most vaporizers added an unknown concentration of vaporized liquid to a measured amount of gas; the Copper Kettle allowed the vapor to be added in known quantities that could be precisely measured and controlled through a separate circuit built into the anesthesia machine. Second, heat is required to convert volatile anesthetics from the liquid to gas form. Most vaporizers were made of glass which conducts heat poorly and so the temperature of the liquid in the vaporizer dropped rapidly in use; the Copper Kettle is made from materials that conduct heat well, keeping the liquid warm. Third, by dispersing the carrier gas through the liquid in a large number of very small bubbles, it further increased the speed and efficiency of vaporization.

The Copper Kettle could be calibrated to vaporize any volatile liquid anesthetic, such as chloroform, ether, halothane (Fluothane), or enflurane (Ethrane). Dr. Morris intended the vaporizer to be carefully adjusted by the anesthesiologist in response to the changing needs of the patient throughout the course of an anesthetic.

Note Type: Acquisition

Notes: This prototype is part of the Lucien E. Morris, M.D. Manuscript Collection,

donated to the Wood Library-Museum of Anesthesiology in 2010 by Dr. Morris

and his family.

Note Type: Exhibition

Notes: Selected for the WLM website (noted August 28, 2015.)